As a well-known company in the reflective material industry, YGM is well aware of the importance of green environmental protection to the sustainable development of enterprises, and has always integrated the concept of green environmental protection into every aspect of corporate development.

In terms of energy: Green power PPA – photovoltaic power generation

Green electricity refers to renewable electricity with zero or close to zero carbon dioxide emissions during the power generation process, with solar energy and wind as the main sources. Companies can effectively reduce carbon emissions in their production and operations by using green electricity. The power purchase method adopted by YGM is to directly sign a Power Purchase Agreement (PPA). PPA can not only provide long-term and stable green power for power-consuming enterprises, but also directly promote new installed capacity, which reflects YGM’s contribution to energy transformation.

Photovoltaic power generation is a technology that uses the photovoltaic effect at the semiconductor interface to directly convert light energy into electrical energy. Compared with commonly used thermal power generation systems, it has the advantages of safety, reliability, no noise, no pollution emissions, no need to consume fuel and erect transmission lines, and high energy quality.

YGM has installed about 6,000-7,000 square meters of solar panels on the roof of the factory, and has started photovoltaic power generation in June 2022, with a monthly power supply of 300,000 kwh, achieving 30% green electricity replacement (YGM’s average monthly electricity consumption is 900,000 kwh) . The electricity bill is 24% off the electricity bill, which is equivalent to a monthly saving of RMB 177,600.

Four reforms were carried out in raw materials

Water-based PU replaces oil-based PU

Water-based PU is produced through a new process using water instead of organic solvents. Compared with oil-based PU, it is more environmentally friendly, with no solvent emissions. The finished product has an obvious green concept and no waste gas, wastewater, and sewage emissions, reducing harm to the environment.

The main purpose of replacing oil-based PU with water-based PU is the transfer process in the intermediate process. It will not have any impact on the performance of the final product, let alone the quality of the product.

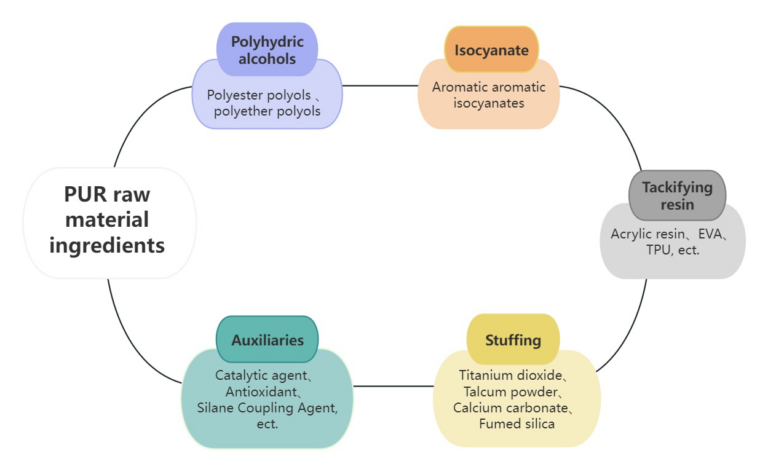

PUR—uses moisture to cure reactive polyurethane hot melt adhesive

PUR hot melt adhesive is a reactive polyurethane hot melt adhesive. It is applied under molten conditions, has a certain initial tack, and reacts with moisture on the surface of the substrate to solidify to produce strong bonding force.

PUR has the following advantages:

- lCure amount 100%

- lZero VOC emission, no fire hazard, environmentally friendly, non-toxic, green and environmentally friendly

- lMoisture curing, no drying process, fast and energy-saving

- lExcellent initial strength and cross-linking curing function, resulting in higher final bonding strength

- lExcellent heat resistance, water resistance, chemical resistance, and durability

- lSingle-component type, easy for industrial automation and mechanized operation, high production efficiency

Recycled yarn fabric products GRS certification (post-consumer)

YGM fabrics successfully obtained the Global Recycled Standard (GRS) certification issued by Control Union. The Global Recycled Standard (GRS) is an international, voluntary and comprehensive product standard that stipulates recycling content, chain of custody, social and environmental practices, and chemistry. Third-party certification requirements for product restrictions. As an advocate and practitioner of sustainable development, YGM insists on using environmentally friendly and consumer-friendly materials in product development and manufacturing processes. GRS certification provides a tracking certification system to supervise and ensure the effective fulfillment of YGM’s product-related commitments.

Recycle PET

Recycled PET film is made by collecting and shredding waste PET products, melting them and making them into thin fabrics. PET is a thermoplastic polymer material with excellent properties and good physical and chemical properties. However, PET is also extremely chemically inert and is difficult to be degraded by air or biodegradation, causing serious environmental pollution and waste of resources. Therefore, PET Recycling has a positive impact on both the environment and the economy.

First of all, the production process of recycled PET is more environmentally friendly than the production process of virgin PET, which can reduce carbon dioxide emissions by 30%-40%. Secondly, by recycling discarded PET products, the pollution of the environment by waste is reduced and the utilization cycle of resources is extended. In addition, the application of recycled PET can also reduce production costs, improve the competitiveness of enterprises, and promote sustainable economic development.

Promote RTO heat energy recovery and production automation in production and processing

RTO heat energy recovery Regenerative Thermal Oxidizer

Regenerative Thermal Oxidizer (RTO) is an effective VOC organic waste gas treatment equipment. It consists of three or more regenerators, one combustion chamber, and six or more main air flow switching valves. The principle is to heat the organic waste gas to above 760 degrees Celsius, so that the VOCs in the waste gas are oxidized and decomposed into carbon dioxide and water. It then passes through another regenerator to store heat and then discharges it. The stored heat is used to preheat the newly incoming organic waste gas. By switching periodically in this way, the organic waste gas can be continuously processed without or with a small amount of energy replenishment, achieving energy saving effects.

RTO can treat almost all waste gases containing organic compounds, and the waste gas purification efficiency is as high as 99%, and the heat recovery efficiency is as high as 95%. It reduces YGM organic waste gas (VOC) emissions by about 12,600 kg/year, saving factory energy consumption by about 120 10,000 KW/year.

Production automation

Production automation refers to a production process that does not require people to directly participate in the operation, but uses mechanical equipment, instruments and automation devices to complete all or part of the processing of the product. At present, YGM has implemented automated operations in three aspects, namely gluing automation, glass bead feeding automation and material flow automation (slitting). Real-time monitoring and control of operations during the production process accurately controls production quality and reduces the number of defective products, thereby greatly reducing production time and costs and improving production efficiency.

——Eden