Non-FR Fluorescent Color Vest Trim

- Item No.: Fluorescent Yellow/Silver: AH002;Fluorescent Red/Silver: AH003

- Reflectivity Coefficient: >400cd/lx/m²

- Backing Fabric: T/C or 100% Polyester

- Color: Fluorescent Yellow/Silver or Fluorescent Red/Silver

- Attachment Type: Sew On

- Wash Performance: Home wash 25 cycles@60℃

- Flame Resistant: No

| Item No. | Fluorescent Yellow/Silver: AH002、Fluorescent Red/Silver: AH003 |

| Reflectivity Coefficient | >400cd/lx/m² |

| Backing Fabric | T/C or 100% Polyester |

| Color | Fluorescent Yellow/Silver or Fluorescent Red/Silver |

| Attachment Type | Sew On |

| Wash Performance | Home wash 25 cycles@60℃ |

| Flame Resistant | No |

More YGM reflective products

Non-FR Fluorescent Color Vest Trim FAQ guide

Table of Contents

YGM promises to enhance visibility and safety. That’s why we have designed a Non-FR Fluorescent Color Vest Trim for individuals seeking extra protection during outdoor activities. This groundbreaking trim offers unmatched visibility in low-light conditions. Whether you’re a cyclist navigating busy streets or a first responder facing challenging situations, our Non-FR Fluorescent Color Vest Trim ensures you stay safe and secure.

Product parameters for Non-FR Fluorescent Color Vest Trim

Understanding the parameters of a product is of utmost importance, as it empowers consumers to make informed decisions. In the case of the Non-FR Fluorescent Color Vest Trim, the following key parameters are included. Each plays a crucial role in its performance and suitability for different applications.

● Reflectivity Coefficient

The reflectivity coefficient is an essential feature of the Non-FR Fluorescent Color Vest Trim, measuring greater than 400cd/lx/m². This high reflectivity ensures superior visibility even in challenging low-light conditions.

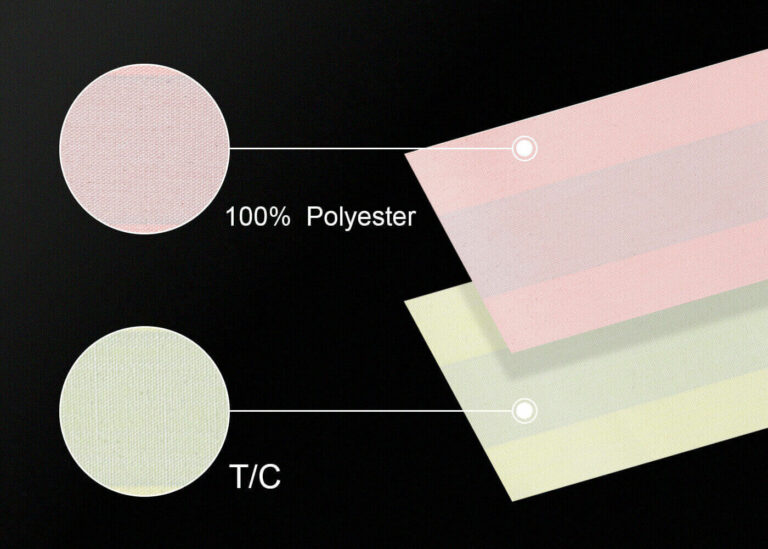

● Backing Fabric

You can choose between two options for the backing fabric: T/C (Terylene/cotton) or 100% Polyester. T/C offers a balance of comfort and durability, while 100% Polyester provides higher resistance to wrinkles and shrinkage.

● Color

The Non-FR Fluorescent Color Vest Trim is available in two vibrant colors: Fluorescent Yellow/Silver and Fluorescent Red/Silver. These eye-catching colors not only enhance visibility but also provide an extra level of safety during daylight hours.

● Attachment Type

The ease of application is a crucial advantage of the Non-Fluorescent Color Vest Trim. Its Sew On attachment type simplifies the process, allowing users to securely fasten the trim to various garments or equipment without hassle.

● Wash Performance

The Non-Fluorescent Color Vest Trim demonstrates excellent wash performance and can withstand 25 cycles of home washing at 60℃ without compromising its reflective properties.

● Flame Resistant

No, the Non-FR reflective warning tape is not flame-resistant. It is suitable for applications where flame resistance is not a requirement.

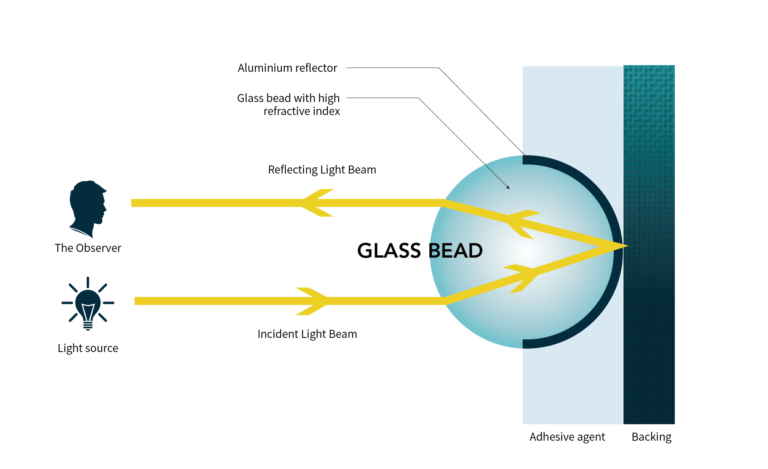

What is the reflective principle of the Non-FR Fluorescent Color Vest Trim?

The reflective principle of the Non-FR Fluorescent Color Vest Trim is retroreflection. Retroreflection allows the trim to bounce light back to its source, enhancing visibility in low-light conditions.

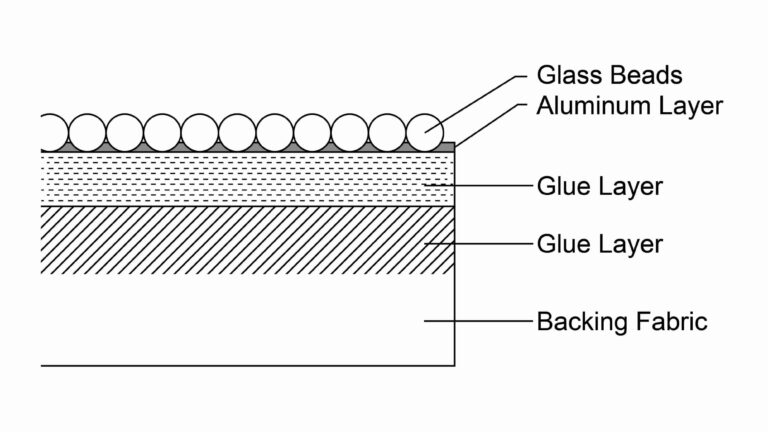

How is the Non-FR Fluorescent Color Vest Trim produced?

The production process of the Non-FR Fluorescent Color Vest Trim involves several key steps.

- Firstly, glass beads are implanted on the protective film in combination with glue.

- Next, aluminum/zinc sulfide plating is done to cover the beads with iron plates on both sides.

- Undercoating and gluing follow, preparing the surface for the next stage.

- Then compounded with the backing fabric, and the phosphor is added.

- After this, the product undergoes curing and rigorous quality inspection to meet the required standards.

- Finally, the trim is cut and packed, ready for customer distribution.

This elaborate process ensures that the Non-FR Fluorescent Color Vest Trim attains high reflectivity and durability, providing optimal visibility and safety for various applications.

What is the structure of the Non-FR Fluorescent Color Vest Trim?

The structure of the Non-FR Fluorescent Color Vest Trim consists of several layers that work together to achieve its high reflectivity and visibility. It typically includes reflective beads that are bead planted on the surface.

These beads are then covered with aluminum/zinc sulfide plating, ensuring durability and enhancing the reflective effect.

How does the Non-FR Fluorescent Color Vest Trim compare to the Flame Retardant Warning Reflective Tape?

The Non-FR Fluorescent Color Vest Trim and the FR warning tape share a similar appearance and belong to the style of warning tape. However, they differ in some key aspects:

- Backing Fabric

FR Warning Reflective Tape is available with backing fabric options of 100% Cotton or 100% Aramid. These materials offer specific benefits such as comfort and flame resistance.

Non-FR Fluorescent Color Vest Trim provides two backing fabric choices – T/C (Terylene/cotton) or 100% Polyester. T/C combines comfort and durability, while 100% Polyester offers enhanced strength.

- Flame Retardancy

FR Warning Reflective Tape possesses good flame retardant properties, making it suitable for applications where fire safety is crucial.

Non-FR Fluorescent Color Vest Trimᅠdoes not have flame-retardant properties, making it more suitable for situations where flame resistance is not required.

While both products serve as warning tapes and enhance visibility in low-light conditions, their differences in backing fabric and flame retardancy allow users to choose the most suitable option based on their specific needs and safety requirements.

Does the Non-FR Fluorescent Color Vest Trim come with any certification?

Currently, the Non-FR Fluorescent Color Vest Trim has no certification. However, YGM has plans to obtain relevant certifications in the future.

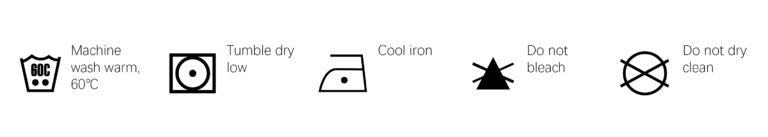

How should I take care of the Non-FR Fluorescent Color Vest Trim?

To ensure the longevity and effectiveness of the Non-FR Fluorescent Color Vest Trim, follow these care instructions:

Storage

Store the trim in a cool, dry area, away from direct sunlight and extreme temperatures. Using the product within one year from receipt is recommended to maintain its optimal performance.

Home Washing Requirements

- Machine wash warm at 60℃

- Do not presoak

- Do not bleach

- Do not dry clean

- Tumble dry low

- Use cool iron

You can maintain the Non-FR Fluorescent Color Vest by following these care instructions.

What are the quality inspection standards for the Non-FR Fluorescent Color Vest Trim?

The quality inspection standards for the Non-FR Fluorescent Color Vest Trim are as follows:

(1) Appearance

The product’s surface should be flat and smooth, free from black spots, scratches, wrinkles, color differences, or any defects that may affect its performance.

(2) Reflectivity

The Retroreflection Coefficient Measuring Instrument is used to measure the initial average reflectivity. A reflective coefficient is measured at 5° entrance, 0.2° observation angles, and 5° entrance, 1° observation angles. The initial average reflectivity should be greater than 400cd/lx/m².

(3) Washability

The product is washed in a Washing Machine, then measured using the Retroreflection Coefficient Measuring Instrument. After washing at 60℃ for 25 cycles, the product’s surface condition is observed, and its reflectivity is tested. The reflectivity after washing should still be greater than 100cd/lx/m².

(4) Indentation test after hot pressing

The Pneumatic Heat Press Machine is used for this test. The product is subjected to hot pressing for 15 seconds with a rope on it. Afterward, the surface condition is observed. A qualified product should not have any black marks or indentations.

Can I customize the Non-FR Fluorescent Color Vest Trim?

Yes, you can customize the Non-FR Fluorescent Color Vest Trim according to your specific needs and preferences. The trim comes in regular sizes of 5cm & 2cm, 7.5cm & 2.5cm, and 10cm & 5cm. However, if you require a different size, custom sizes are accepted to suit your unique requirements.ᅠWe can also customize different styles, such as perforation and logo engraving.

What is the difference between T/C and 100% Polyester used in the Non-FR Fluorescent Color Vest Trim?

The difference between T/C (Terylene/cotton) and 100% Polyester used in the Non-FR Fluorescent Color Vest Trim is as follows:

T/C:

- T/C is a fabric produced by blending polyester and cotton fibers together. It combines the desirable qualities of both materials.

- It is known for its good texture and high strength, making it a durable and reliable choice for various applications.

- The T/C blend balances the comfort of cotton and the added strength of polyester.

100% Polyester:

- 100% Polyester fabric used in the trim is made entirely from polyester fibers.

- It has a soft and lightweight texture, providing a comfortable wearing experience.

- Polyester is highly durable and can withstand regular washing and wear without losing its quality.

- It is easy to wash, making it convenient for maintaining the cleanliness and longevity of the trim.

What is the minimum order quantity?

The minimum order quantity (MOQ) for the Non-FR Fluorescent Color Vest Trim designed for clothing is 300 square meters. This means that to order this trim, the minimum quantity required is 300 square meters of the product.

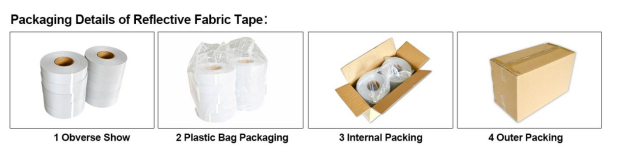

How is the Non-FR Fluorescent Color Vest Trim packaged?

The Non-FR Fluorescent Color Vest Trim is typically packaged securely and protectively to ensure its safe delivery to customers. The specific packaging method may vary based on the manufacturer or supplier’s practices.

Where can the Non-FR Fluorescent Color Vest Trim be used?

The Non-FR Fluorescent Color Vest Trim can be sewn onto safety clothing, hats, backpacks, gloves, and more to improve visibility in low light and night conditions. You can also use Non-FR sew on reflective tape. Its fluorescent properties make it highly visible during the day and dusk, ensuring safety in various situations.