Advertisement Grade Reflective Sheeting

- Two types: PET type and Acrylic type

- Feature: PET type: Untearable, easy operation, easy for computer cutting; Acrylic type: Tearable, can be screen printed, good extensibility, easy for computer cutting

- Service life: 3 years

- Feasible operating temperature: PET type: 5-30℃; Acrylic type: 18-28℃

- Color: Regular colors are white, yellow, red, green, blue, orange, brown and black. Accept customized.

- Applications: Advertisement signs, propagandistic signs, temporary work zone signs, etc.

| Two types | PET type and Acrylic type |

| Feature | PET type: Untearable, easy operation, easy for computer cutting; Acrylic type: Tearable, can be screen printed, good extensibility, easy for computer cutting |

| Service life | 3 years |

| Feasible operating temperature | PET type: 5-30℃; Acrylic type: 18-28℃ |

| Color | Regular colors are white, yellow, red, green, blue, orange, brown and black. Accept customized. |

| Applications | Advertisement signs, propagandistic signs, temporary work zone signs, etc. |

More YGM reflective products

Advertisement grade reflective sheeting FAQ guide

Table of Contents

YGM manufactures and markets advertising grade reflective sheeting, unprintable, untearable, with a 3 year warranty for temporary road signs made in China. With our many quality safety products in stock and professional service, we are one of the most trusted safety product manufacturers in China.

Advertising Grade Reflective Sheets are also called Commercial Grade, Economy Grade, and so on. Advertising Grade Reflective Sheeting is more cost-effective than other reflective sheeting series, but it has a weaker reflective feature than high-intensity reflective vinyl, so it is suitable for situations where a high degree of reflection is not required. These signs are specifically designed for economical use, durability, and personalization. For example, they are widely used in advertising graphics, promotional signs, parking lots, mining sites, construction zones, and character decoration. Check out our FAQ Guide below if you want to learn more about Advertising Grade Reflective Sheeting.

Advertisement grade reflective sheeting description

Reflective sheets like these are used in advertising. The surface can be improved with Solvent Ink-jet printing so it won’t launder, and that it can be printed but not lacerable for extensive usage. These sheets are used for advertisement signs, propagandistic signs and temporary work zone signs cutting stickers because of their excellent reflectivity and durability.

Figure 1: Advertising Grade Reflective Sheeting

Features of advertisement grade reflective sheeting

- Microbeads are embedded in the glass surface.

- A range of types is available, including weather-resistant and UV-protected types.

- The product is waterproof, highly visible, highly conspicuous, self-adhesive and highly reflective.

- As well as temporary traffic signs, it is widely used to create traffic signs and safety signs on city roads and common grade roads.

- The company offers a logo and printing service for customers.

- We can customize the size and design, OEM is an option.

Commercial grade reflective sheeting application

- Advertisement graphic with reflective elements

- Building promotional signs with reflective elements

- Reflective construction signs for the outdoors

- Construction of barricades

- Work zone signs for temporary projects

- Motorcycle helmet reflective sticker.

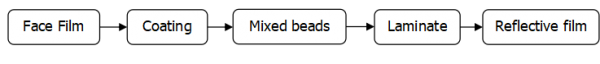

Production process of commercial grade reflective vinyl

Figure 2: Advertising Grade Reflective Sheeting

It is the easiest production process for enclosed glass beaded reflective sheeting to produce advertising grade reflective sheeting. A commercial grade reflective vinyl produced using PET is shown in figure 2. Outdoor durability varies based on weather conditions. The face film is PET. The glass beads are coated onto PET vinyl. Since it is an economical grade reflective vinyl, we are mixing glass beads with adhesive. For the reflective layer, aluminum coating is applied, followed by the application of permanent adhesive and the layer of release paper. This completes the process.