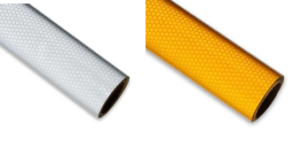

High Intensity Grade Reflective Sheeting

- Three types: PET type, PC type and PVC type

- Feature:PET type: Untearable, high reflectivity ability;PC type: Untearable, can be screen printed, high reflectivity ability; PVC type: Untearable, good for screen printing and ink-jet printing

- Service life: PET type: 5 years; PC type: 7 years; PVC type: 3 years

- Feasible operating temperature: All are 5-30℃

- Color: Regular colors are white, yellow, red, green, blue,brown. Accept customized.

- Applications: Usually used to stick on traffic signs of highways and city roads, cars, ships and other vehicles.

| Three types | PET type, PC type and PVC type |

| Feature | PET type: Untearable, high reflectivity ability |

| PC type: Untearable, can be screen printed, high reflectivity ability | |

| PVC type: Untearable, good for screen printing and ink-jet printing | |

| Service life | PET type: 5 years |

| PC type: 7 years | |

| PVC type: 3 years | |

| Feasible operating temperature | All are 5-30℃ |

| Color | Regular colors are white, yellow, red, green, blue,brown. Accept customized. |

| Applications | Usually used to stick on traffic signs of highways and city roads, cars, ships and other vehicles. |

More YGM reflective products

High intensity grade reflective sheeting FAQ guide

Table of Contents

As a leading manufacturer of reflective fabric and reflective tape sheeting, YGM manufacturer mainly provides & manufactures top-quality reflective fabric to distributors around the world. Whether it’s the quality control or the production time, YGM is always at your service, meeting your reflective self-adhesive vinyl specifications as best as it can. In order to help you learn more about our product, YGM has compiled some frequently asked questions.

Detailed description of high intensity grade reflective sheeting.

One kind of reflective sheeting from YGM is the high-intensity grade, with a seal structure and 3 times higher reflection value than engineer grade reflective vinyl, allowing drivers to read traffic signage information in time, reducing the chances of traffic accidents, and used as highway reflective traffic signage and road construction warning signs. Aside from corrosion resistance oil adhesive, our products include OEM highways printable reflective sheeting.

Figure 1: High Intensity Grade Reflective Sheeting

An additional description.

- A reliable source of visibility.

Signs that are bright and visible will help drivers react quickly. It returns more light to drivers than glass beaded retroreflective sheeting, resulting in better visibility. Performance standards for middle grades are met in most cases.

- It is great for a variety of imaging methods.

Select ink-jet printing and screen print imaging methods are compatible with it.

- Designed to withstand daily wear and tear.

In extreme climates, a tough topcoat helps signs resist scuffs, scratches, and gouges. This reduces the need for replacements and the costs associated with them.

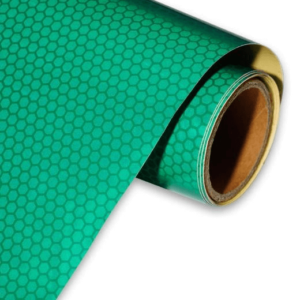

Materials for reflective sheeting

It consists of a reflective layer made up of glass beads and certain polymer materials, such as PVC, PET, and PC, that is used to make traffic signs and license plates.

Figure 2: Flexible High Intensity Grade Reflective Sheeting

Application of reflective sheeting.

The use of reflective sheeting is primarily limited to traffic signs on roads, railways, construction zones, vehicle license plates, barricades and helmet stickers. Reflective sheeting with non-metalized micro prismatic lenses is designed for traffic control signs, work zone devices, and delineators.

Reflective film sheeting operates at a certain temperature.

Reflective sheeting typically contains pressure-sensitive adhesive and should be applied at a temperature between 5 and 30 degrees Celsius to the sign substrate.

Difference in reflective sheeting signs’ using life.

After a certain period of time, the reflective sheeting will lose its reflection value when used in an environment that doesn’t provide protection. As a result, YGM divides road reflective film into different standards according to its reflective value.

- A standard for reflective sheeting tape.

In order for reflective tape to have a high reflection value and outdoor life, the grade of reflective film must be high intensity grade, and the raw reflective material must be used and the price must be different. For example, highway reflective signs can be made using the grade reflective sheeting, which has a high reflection parameter at a high price. However, low-reflective films are sufficient for making reflective street signs. To put it simply, you can choose reflective tape in different standards depending on your needs.