Glow in the Dark Flame Retardant Reflective Tape for Clothing

- Reflectivity: >400cd/lx/m²

- Luminous intensity: ≥4000mcd/㎡

- Color:Beige & Silver

- Width: 5cm, 10cm or customized sizes

- Backing fabric: 100% cotton or 100% aramid

- Attachment Type: Sew On

- Washability: 25 cycles@60℃

| Reflectivity | ﹥400cd/lx/m² |

| Luminous intensity | ≥4000mcd/㎡ |

| Color | Beige & Silver |

| Width | 5cm, 10cm or customized sizes |

| Backing fabric | 100% cotton or 100% aramid |

| Attachment Type | Sew On |

| Washability | 25 cycles@60℃ |

More YGM reflective products

Glow in the Dark Flame Retardant Reflective Tape for Clothing FAQ guide

Table of Contents

YGM leads the safety industry with its groundbreaking glow in the dark flame retardant reflective tape. This product is perfect for anyone who needs extra visibility and safety, whether you’re an outdoor enthusiast or a professional. From cyclists to firefighters, our tape can help keep you safe and secure.

The below FAQ guide helps you understand more about the tape’s performance and capabilities.

What are the luminous and reflective principles of glow in the dark flame retardant reflective tape for clothing?

The following are the main principles:

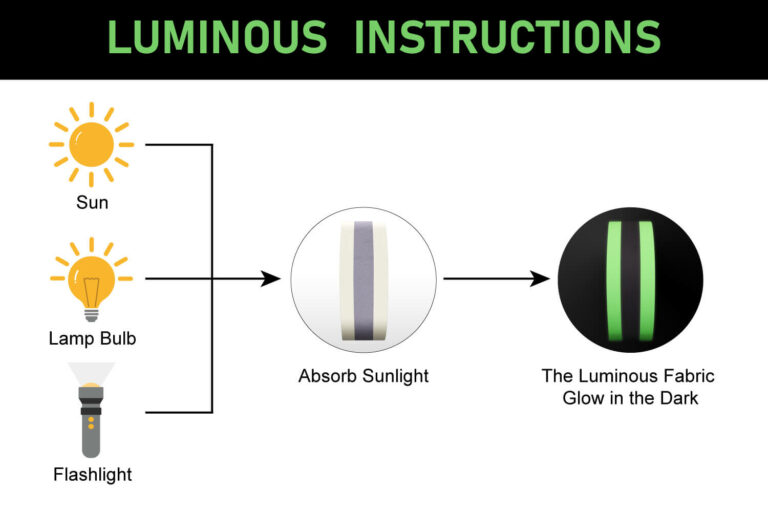

(1) Luminous Principle

Luminescent substances can absorb light energy when exposed to a certain light level and emit it in a dark environment to create a glowing effect. They can repeat this cycle by continuously absorbing and releasing light energy. For glow in the dark flame retardant reflective tape for clothing, specially formulated phosphors are used to produce a strong visible light.

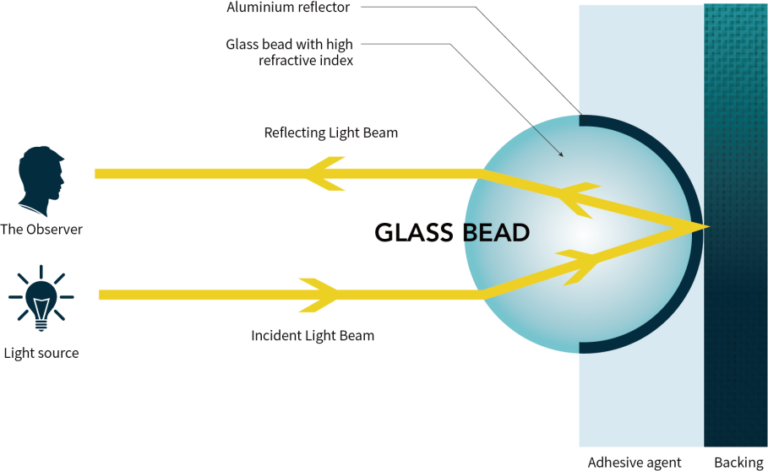

(2) Reflective Principle

Reflective materials reflect the brightness of the incident light to its source so that they can be seen from a long distance at night. This capability is also known as retroreflection. The reflective material usually uses glass beads to form a refractive index difference on the material’s surface, which will cause edge reflection and increase the visibility of the material.

What are the performance parameters for glow in the dark flame retardant reflective tape for clothing?

It is very important to consider the performance parameters of the reflective tape for clothing before opting for it. The performance parameters include:

● Material and Color:

The Glow in the Dark Flame Retardant Reflective Tape for Clothing, item number H002-LU, is made of 100% cotton or 100% aramid material. It is designed in beige, offering a subtle and neutral appearance. This tape has high-performance features that enhance visibility and safety in various environments.

● Reflection Coefficient:

The reflection coefficient of the tape exceeds 400cd·1x-1·m-2, ensuring excellent visibility even in low-light conditions.

● Luminous Intensity and Glow Time

With a luminous intensity of at least 4000mcd/㎡, this tape emits a strong and vibrant glow, further enhancing its visibility. The tape’s glow time lasts 8 hours, allowing for prolonged visibility even after the initial light exposure.

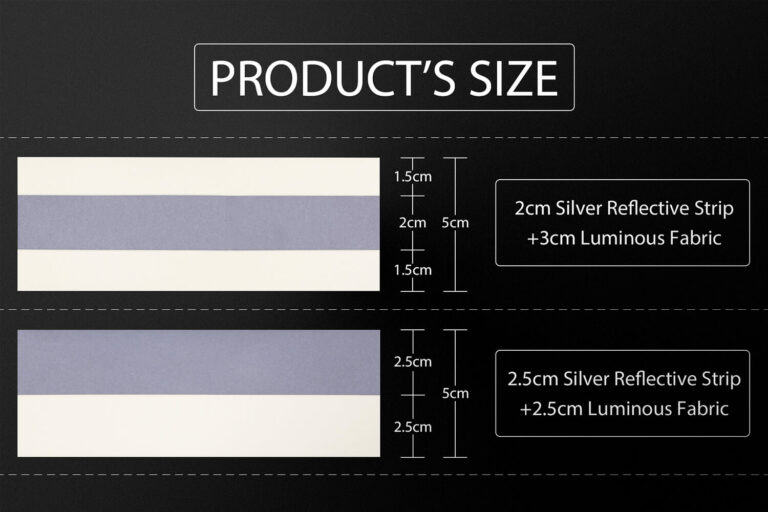

● Variety of Sizes

The tape is available in two different size options: 5&2 and 2.5&2.5. The first size comprises 3cm of luminous fabric and a 2cm reflective strip, while the second features 2.5cm of luminous material combined with a 2.5cm reflective strip. These size variations offer flexibility to suit different clothing or accessory requirements.

● Flame Retardancy

In terms of flame retardancy, the tape demonstrates exceptional resistance to open fire for over 5 seconds, meeting the rigorous standards set by ГОСТ 53264-2009п.7.14, the Russian flame retardant regulations. This quality ensures the tape provides a reliable protective barrier in potentially hazardous situations.

● Washing Performance

Furthermore, the tape has undergone rigorous washing tests, enduring 25 cycles of washing at 60°C. This testing demonstrates its durability and ability to maintain performance parameters even after multiple washes, ensuring long-lasting functionality and reliable visibility.

What is the production process of the glow in the dark flame retardant reflective tape for clothing?

To make it more comprehend, we cut the procedure into the following points:

- The production process of the glow in the dark flame retardant reflective tape for clothing begins with bead planting, where glass beads are embedded onto the glue. These beads serve as the reflective components of the tape.

- Next, the tape undergoes aluminum or zinc sulfide plating to enhance its reflective properties.

- After plating, an undercoating is applied to the backing fabric’s surface to improve the adhesion.

- Gluing is then performed to securely attach the beaded film to the backing fabric.

- Put the tape in the oven for curing, and judge the degree of curing of the product by whether the washing performance is qualified

- Following curing, rigorous quality inspections are conducted to assess performance and adherence to specifications.

- Finally, the tape is slit into the desired width and length configurations and packed for distribution, ensuring it is protected and ready for use in various clothing applications.

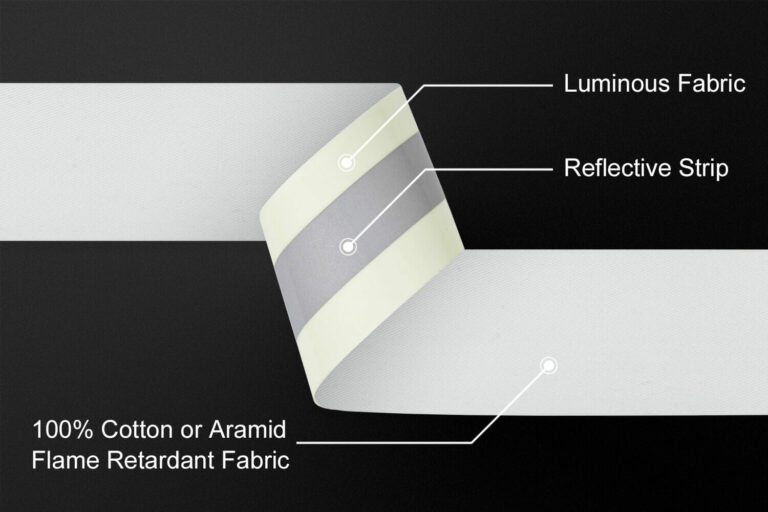

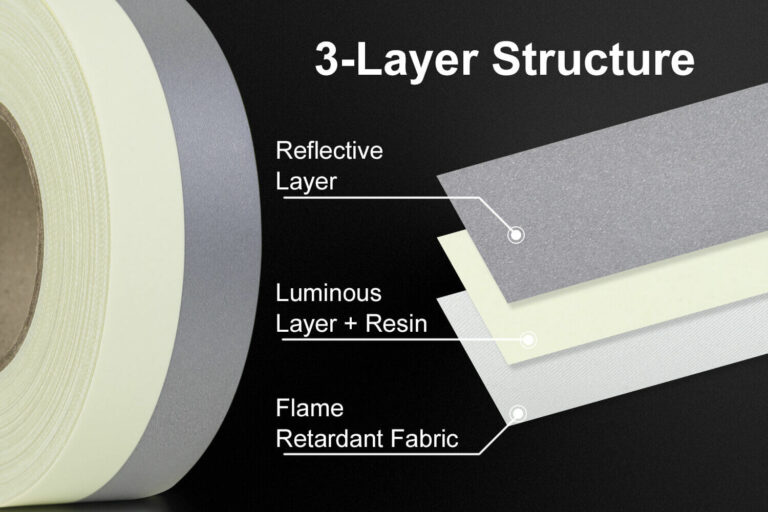

What is the product composition of the glow in the dark flame retardant reflective tape for clothing?

The glow in the dark flame retardant reflective tape for clothing is composed of three layers.

- The top layer is a reflective material that enhances visibility by reflecting light to its source.

- The middle layer comprises a luminous layer combined with a resin, allowing the tape to store and emit light energy in dark conditions.

- The bottom layer is 100% cotton or aramid flame-retardant fabric, providing durability and flame resistance.

These three layers work together to create a tape that offers high visibility, luminescence, and flame-retardant properties for enhanced safety in clothing applications.

How long does it take for glow in the dark flame retardant reflective tape for clothing to absorb light before it can shine?

After absorbing light for 10 minutes, the luminescence is visible to the naked eye under dark conditions and lasts for over half an hour. The glow becomes lighter as the duration of luminescence increases. The specified standard is ГОСТ 53264-2009п.7.19, which is a federal standard in Russia primarily for producing special protective clothing for firefighters and other similar professions.

What is the size of glow in the dark flame retardant reflective tape for clothing?

The glow in the dark flame retardant reflective tape for clothing comes in various sizes to accommodate different needs. The regular widths available are 5cm, 10cm, 12cm, and so on. However, the tape can be cut into various widths to meet specific customer requirements.

How long does the glow in the dark flame retardant reflective tape for clothing last?

The glow in the dark flame retardant reflective tape for clothing has a common luminous time of either 5 or 8 hours. The specific luminous time may vary depending on factors such as the intensity and duration of light exposure, but these are the typical durations for the tape’s glowing effect.

Under what conditions should the glow in the dark flame retardant reflective tape for clothing be stored?

Storing this product in cool and dry conditions is recommended and should be used within 1 year.

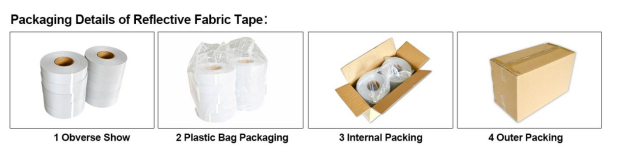

What is the packing method of glow in the dark flame retardant reflective tape for clothing?

The packing method of the glow in the dark flame retardant reflective tape for clothing varies depending on the size. The 5cm width tape is typically packed with 10 rolls per carton. Packaging quantities and arrangements are adjusted accordingly to ensure efficient and secure transportation and storage of the tape.

During the production process, how to ensure and detect the quality of glow in the dark flame retardant reflective tape for clothing?

The following tests are conducted to ensure the quality of glow in the dark flame retardant reflective tape for clothing

- Flame Retardant Performance Testing Standard

- a) The sample must not ignite.

- b) The sample must not burn or have any layer perforated.

- c) Do not ignite the sample or allow any molten residue.

- d) The burning time should not last longer than 2 seconds after it has been lit.

- Heat Resistance Performance Standard

The backing fabric showed no signs of carbonization or peeling after being heated in the oven for 5 minutes.

- Tear Strength Standard

We perform a tear resistance test on the item produced under workshop conditions, both in the warp and weft directions, 24 hours later. If the standard sample passes the test, it meets the quality standards.

- Appearance

The surface is smooth and free of black spots, wrinkles, or other imperfections.

- Washability Standards

The luminous effect remains even after washing 25 times at 60℃. Additionally, other regular luminescent products are not able to withstand washing.

Can the glow in the dark flame retardant reflective tape for clothing be customized?

Yes, the glow in the dark flame retardant reflective tape for clothing can be customized according to specific requirements. It can be perforated for cutting at particular intervals. Additionally, the tape allows printing logos on the backing fabric for branding or identification purposes. Moreover, the tape size can be customized to meet individual needs and preferences.

What is the MOQ of glow in the dark flame retardant reflective tape for clothing?

The minimum order quantity (MOQ) for the glow in the dark flame retardant reflective tape for clothing is 200 square meters.

What is the application of glow in the dark flame retardant reflective tape for clothing?

The glow in the dark flame retardant reflective tape for clothing is applied by sewing it directly onto flame-retardant garments. It provides a strong warning effect and durability, ensuring increased visibility and safety for the wearer.