Neon HTV

- Color: neon color (can show bright colors in normal light)

- Multiple styles: PU, PVC, 3D, Luminescence, Glitter

- Composition: PET+PU+TPU

- Application: It’s suitable for several areas of uses like decorations, branding, patches, reinforcement, logos etc.

| Color | neon color (can show bright colors in normal light) |

| Multiple styles | PU, PVC, 3D, Luminescence, Glitter |

| Composition | PET+PU+TPU |

| Application | It’s suitable for several areas of uses like decorations, branding, patches, reinforcement, logos etc. |

More YGM reflective products

Neon HTV FAQ guide

Table of Contents

Our neon heat transfer vinyl allows you to create unique, custom designs. You will be able to create something truly original whether it is on hats, bags, clothes or shoes. YGM provides you with answers to some of the most frequently asked questions about neon htv.

Neon htv: everything you need to know

This neon heat transfer vinyl is ideal for all you crafters and hobbyists out there. You can iron or heat press your design onto fabric craft items or garments by simply planning and cutting your design. The neon vinyl from YGM is thin, elastic, and soft to the touch, now available in bright fluorescent colors.

The vinyl designs are produced in a heat transfer process, which ensures that they are long-lasting and durable for decorations, branding, patches, reinforcements, and logos, etc. The product is available in a variety of neon colors for an extra eye-catching look

Figure 1: Neon HTV

Instructions for application

- The temperature should be between 130℃ and 160℃ for multilayers or thick cotton

- Hold for 10~15 seconds

- A high temperature

- Pressure that is high and even

- Cutting in reverse

- Fabrics made from cotton, polyester, Elastan, or blends of these materials.

- You should wait 24 hours before you wash for the first time. The water should be warm to cold, and the clothes should be tumble dried. It is not advisable to use bleach also dry cleaning is not recommended.

A step-by-step guide

- Place the material liner side down and cut the design. Make sure your design is reversed or mirrored when cutting

- Excess vinyl should be weeded

- Your design should be placed with the liner side up on your garments

- Using high and even pressure, press for 10-15 seconds at a temperature of 130°C – 160°C

- Peel off the liner after cooling

Figure 2: Neon HTV on T-shirt

Additional instructions

Materials such as dazzle cloth, shiny polyester materials, and coated polyester materials should be applied as follows:

Use rubbing alcohol (isopropyl alcohol) to dampen a cloth, then apply it gently to the garment area. Allow the material to dry before applying it. By doing so, the adhesive will be able to penetrate the garment more effectively.

Before pressing your design, we highly recommend washing and drying your garments. In addition, the adhesive will have a better chance of penetrating the garment this way.

Here are some tips and tricks

- It is recommended to test cut

- The settings can vary depending on the cutter and the sharpness of the blade

- You should wash inside out for best results

- Prior to pressing your designs on shiny polyesters and dazzle cloth, we strongly recommend washing and drying your garments.

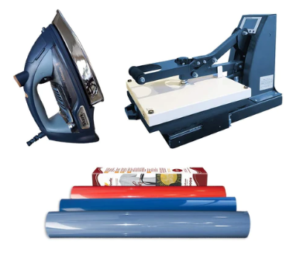

Perfect for ironing or using a heat press

The vinyl can be applied easily with HTV. Your HTV designs can be created using any heat press machine or household flat iron.

The material used in our heat transfer vinyl is more durable and washable than those used by other companies. The colors of your designs will remain vibrant after 50 washing cycles without fading, peeling or cracking. Whenever you wash for the first time, wait 24 hours before you wash again.

Figure 3: Iron and Heat Press