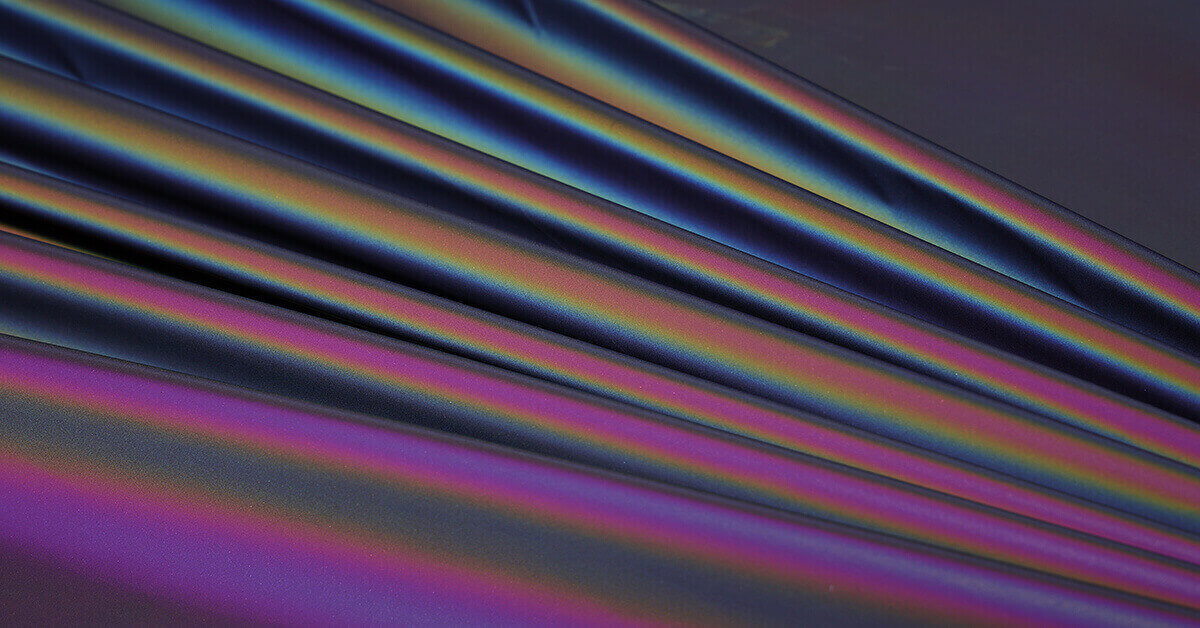

Reflective fabric is used in various applications, from running gear to cycling jackets. Most people think of bright colors and patterns when they see the reflective fabric, but there are a few different ways to process it in order to create those eye-catching designs.

This blog post will take a closer look at the most common methods used to process reflective fabric. Stay safe while running, biking, or walking at night by being seen with some brightly shining reflective gear!

Processing methods of reflective fabric- a quick walk around

How reflective fabric is made can determine its effectiveness at doing its job. This is because the way it is processed affects the quality of the finished product. There are a few different methods that can be used, and each has advantages and disadvantages. Here are some of the most common methods for processing reflective fabric.

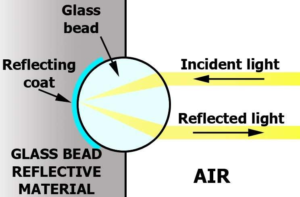

1. Glass Bead Coating Method

Figure 1. Working of Glass Bead

The Glass bead coating method is a popular reflective fabric manufacturing method. It involves coating glass beads onto the fabric surface. The beads are usually made of borosilicate glass, which is a type of heat-resistant glass. The size of the beads ranges from 0.5 to 1mm.

They are usually applied to the fabric using a machine called a reflectometer. The reflectometer applies pressure to the beads, which causes them to adhere to the fabric’s surface. This method is often used to produce reflective fabrics for safety clothing, such as vests and jackets.

It is also used for other applications, such as tents and tarps. It is a relatively simple and quick process. It also produces a fabric that is highly reflective and durable.

Advantages of using the glass bead coating method

The glass bead coating method is a popular way to add reflective properties to the fabric. This method involves coating the fabric with a thin layer of glass beads. There are several advantages to using this method, including the following:

- The glass bead coating process is relatively simple and can be easily controlled.

- The resulting fabric is highly reflective, making it ideal for use in safety garments and other applications where visibility is important.

- The beads can be applied in various patterns, allowing for greater creativity in design.

- The glass bead coating method is compatible with many fabrics, including synthetic and natural fibers.

- The processed fabric is durable and long-lasting, providing excellent value for the customer.

2. Bead planting method

The glass planting method is a manufacturing process used to create reflective fabric. It begins with a thin layer of glass beads placed on a substrate, such as cloth or paper. The glass beads are then heated, melting them into the substrate.

Once cooled, the resulting fabric is highly reflective and can be used in a variety of applications. One benefit of the glass planting method is that it creates a uniform surface, which is essential for reflectivity. Additionally, the process can be easily scaled up or down, making it suitable for both large-scale production and small-scale craft projects.

3. Transfer method

The transfer method is a common method used for manufacturing reflective fabric. A design is first printed onto release paper using special printable ink. The design is then transferred onto the fabric using a heat press. The heat press melts the ink, which bonding it to the fabric.

This method is ideal for producing high-quality reflective fabric, resulting in a strong bond between the ink and the fabric. However, it is also more expensive than other methods.

4. Hot melt-back coating method

The hot-melt back-coating method is a unique way to create highly reflective fabric. This manufacturing process begins with a base fabric that is coated with a layer of hot-melt adhesive. The adhesive is then cured, and the fabric is passed through a series of rollers.

This process helps to distribute the adhesive evenly and creates a smooth, consistent surface. Next, a layer of metalized film is applied to the adhesive. The film reflects light, which helps to make the fabric more visible in low-light conditions. Finally, the fabric is cooled and passed through the second set of rollers.

Best method for processing reflective fabric

There are a few different ways to process reflective fabric, but the best method is glass bead coating. This method helps to ensure that the fabric is evenly coated with reflective materials, resulting in a more consistent shine.

Additionally, the glass beads used in this process are less likely to be scratched or damaged than other types of reflectors. As a result, they will maintain their reflective properties for longer periods.

However, the glass bead coating method is a bit more expensive than other processing methods. As such, it may be the best option for every project. Ultimately, the best processing method for reflective fabric depends upon the specific needs and budget of the project.

YGM- a high-quality manufacturer of reflective fabric

YGM is a high-quality manufacturer of reflective fabric. The company uses state-of-the-art machinery to produce its fabric, which is used in various applications, including road safety, construction, and general visibility. The company uses a special process to create a durable, long-lasting product that resists fading and tearing.

In addition, the fabric is highly breathable, making it ideal for various climates. Because of its superior quality, YGM’s fabric is used by some of the world’s leading outdoor brands. Reflective fabric is essential in many industries because it helps to increase visibility in low-light conditions. For example, road workers often use reflective fabric to ensure they are visible to drivers at night.

The company takes pride in its high-quality fabric and attentive customer service, making it a trusted industry name. YGM has become a leading manufacturer of reflective fabric thanks to its dedication to quality. Contact us to learn more about our products.